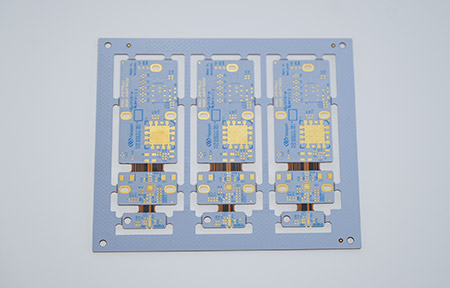

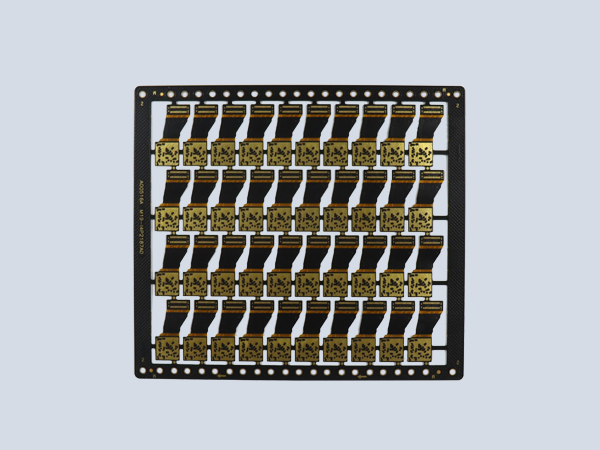

FPC(flex PCB) for data collection

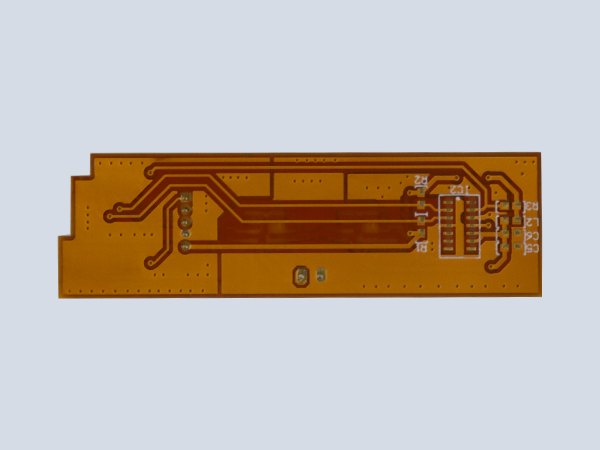

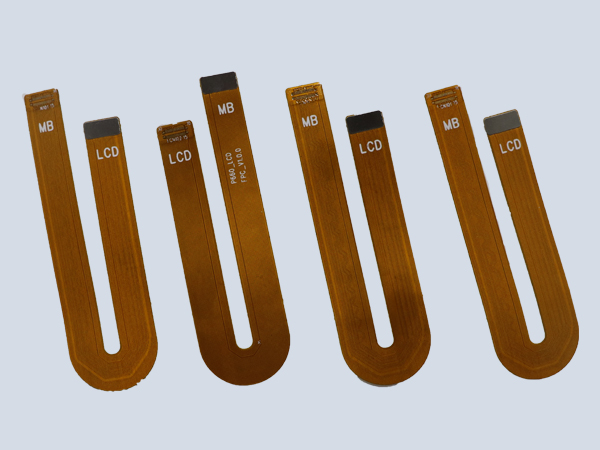

FPC flexible circuit board is mainly used in the connection parts of electronic products, such as mobile phone cables, LCD modules, etc. Compared with hard boards, it has a smaller volume and lighter weight, and can achieve advantages such as bending and bending, three-dimensional assembly, etc. Generally, most soft boards require components to be attached.

Phone:15361676619

Flexible Printed Circuit Board (FPC), also known as "flexible board" in the industry, is a printed circuit board made of a flexible insulating substrate (primarily polyimide or polyester film). It offers many advantages over rigid PCB. For example, it is smaller and lighter, and can be bent, rolled, and folded freely. FPC can significantly reduce the size of electronic products, meeting the needs of the trend towards higher density, miniaturization, and higher reliability. Therefore, FPC is widely used in aerospace, mobile communications, laptops, computer peripherals, PDAs, digital cameras, and other fields.

FPCs are widely used in the following areas:

1. Laptops, LCD monitors, optical drives, and hard drives;

2. Printers, fax machines, scanners, and sensors;

3. Mobile phones, mobile phone batteries, walkie-talkies, mobile phone antennas, dual-SIM cards, and mobile phone cables;

4. Various high-end cameras, digital cameras, digital video cameras, and DVs;

5. VCR heads, laser heads, CD-ROMs, VCDs, CDs, and DVDs;

6. Aerospace, satellite/medical equipment, instruments, and automotive instruments;

7. Light strips, LED FPC flashlights, toys, collars, and decorative lighting.

| material | FPC | Number of layers | 4 |

| copper thickness | 1oz | Plate thickness | 0.2mm |

| Minimum aperture | 0.15mm | Min. trace spacing | 0.065mm |

| Min. trace width | 0.065mm | Surface Treatment | Immersion Gold |