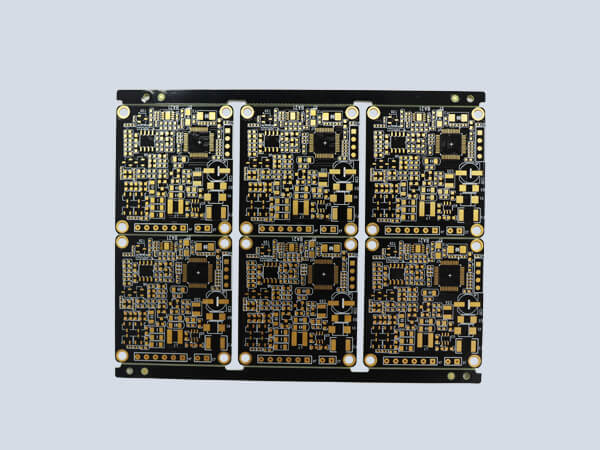

FR-4 + RO mixed laminated PCB

In the manufacturing of PCBs, the lamination process usually refers to the stacking of copper foil, semi cured sheet, and pre wired core board (inner layer) in a certain order, and then using a press machine to first heat press and integrate them under high temperature and high pressure conditions, and then cold press to release stress and ensure the flatness of the product.

Phone:15361676619

In PCB manufacturing, the lamination process typically involves stacking copper foil, prepreg, and the pre-wired core (inner layer) in a specific order. The lamination process then passes through a press, initially hot-pressing the layers under high temperature and pressure to fuse them together. Cold-pressing then releases stress and ensures a flat product.

PCB is a crucial component in the electronics industry. Virtually every electronic device, from watches and calculators to computers and communications equipment, requires a PCB to interconnect electronic components such as integrated circuits.