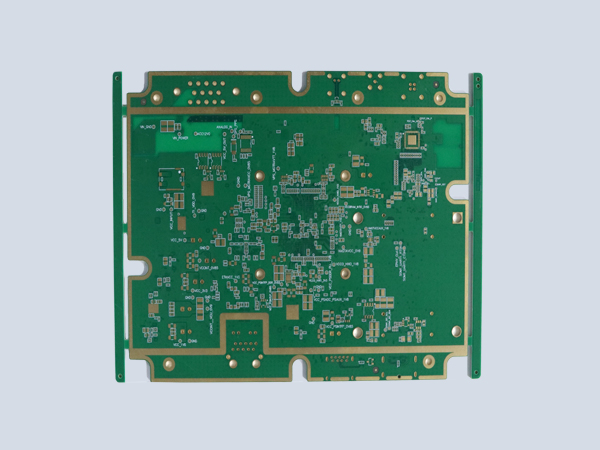

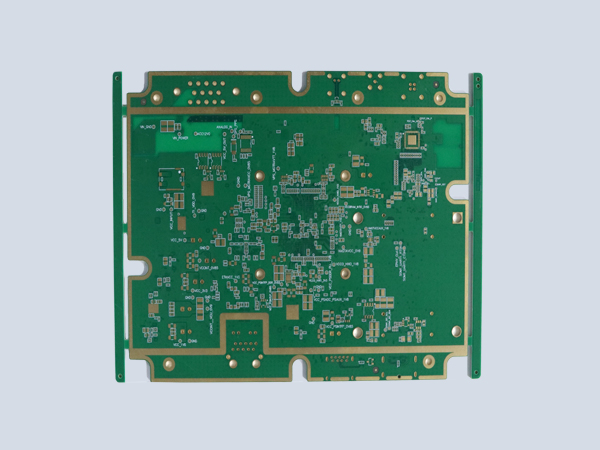

High speed PCB design generally uses multi-layer circuit boards, which are actually composed of several etched single or double boards laminated and bonded together. Compared with single-layer and double-layer circuit boards, multi-layer circuit boards have many advantages, especially in small-sized electronic products. Below, we will share with you the advantages of multi-layer circuit boards.

1. Multilayer circuit boards have high assembly density and small volume. With the decreasing size of electronic products, higher requirements have been put forward for the electrical performance of PCBs, and the demand for multi-layer circuit boards is also increasing. 2. Multilayer circuit boards are used for convenient wiring. The wiring length is greatly reduced, the connection between electronic components is shortened, and the speed of signal transmission is also improved. 3. For high-frequency circuits, adding a ground plane will result in a constant low impedance of the signal line to ground, greatly reducing the circuit impedance and improving the shielding effect. 4. For electronic products with high heat dissipation requirements, multi-layer circuit boards can be equipped with metal core heat dissipation layers to meet the needs of special functions such as shielding and heat dissipation. In terms of performance, multi-layer circuit boards are superior to single and double boards, but the more layers there are, the higher the manufacturing cost, the longer the processing time, and the more complex the quality inspection. However, under the same cost comparison of the same area, although the cost of multi-layer circuit boards is higher than that of single and double layers, considering the noise reduction lamp factor, the cost difference between the two is not so significant. With technological advancements, PCB boards now have over 100 layers and are mostly used for aerospace instruments and medical equipment. In the case of a large number of interconnection and crossover requirements, in order to achieve satisfactory performance of the circuit board, it is necessary to extend the board layer to two or more layers, thus giving rise to multi-layer circuit boards. Therefore, the original intention of manufacturing multi-layer circuit boards is to provide greater freedom in selecting appropriate wiring paths for complex and/or noise sensitive electronic circuits. In multi-layer circuit boards, 4-6 boards are quite common, and the computers we are familiar with are also very common in daily life. The difference between four layer and six layer boards is that there are two internal signal layers between the middle layer, ground layer, and power layer, while six layer boards are thicker than four layer boards. Single and double-layer boards are easy to distinguish and can be discerned with the naked eye. When you hold the board and look at the light, except for the wiring on both sides, everything else is transparent. But for four layer and six layer boards, if there are no corresponding markings on the board, it is not easy to make a simple distinction. Multilayer circuit boards are used for professional electronic devices, especially when they are overloaded in terms of weight and volume. However, this can only be achieved by increasing the cost of multiple substrates in exchange for increasing space and reducing weight. In high-speed circuits, multi-layer circuit boards can provide printed circuit board designers with two or more layers of board surface for wiring, as well as large grounding and power supply areas. Overall, multilayer circuit boards have been widely used in the manufacturing of electronic products due to their flexibility in design, economic superiority, and stable and reliable electrical performance.