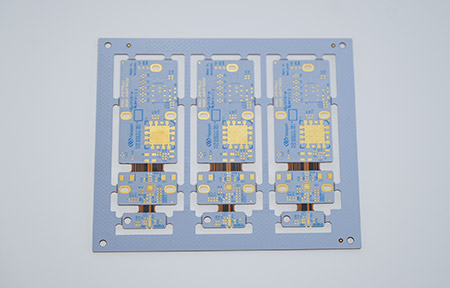

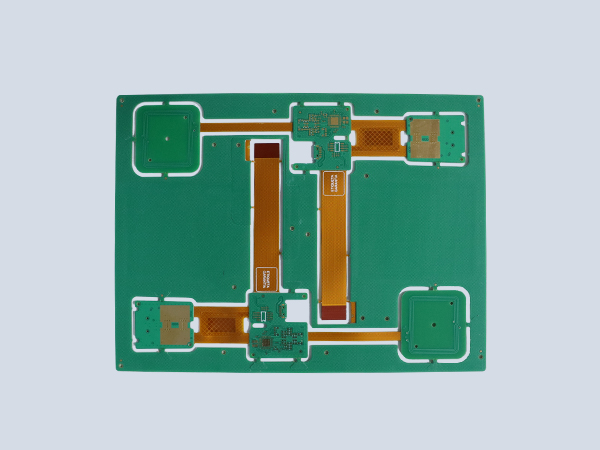

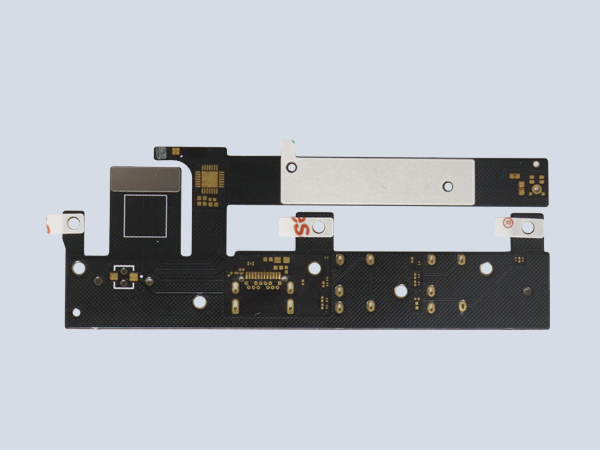

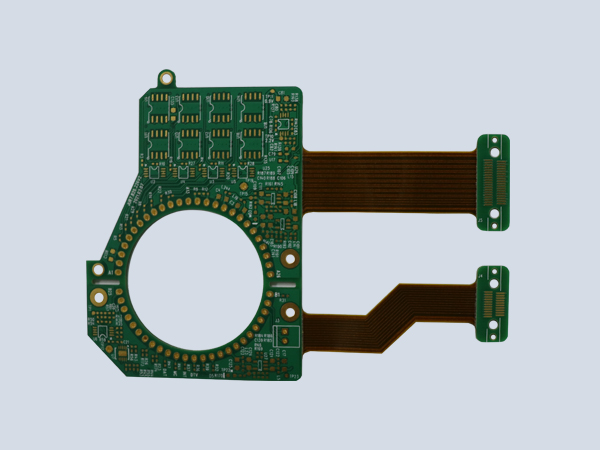

Rigid and flex PCB

Rigid-flex PCB refers to a circuit board with FPC and PCB characteristics formed by combining flexible and rigid circuit boards through pressing and other processes according to relevant process requirements.

Phone:15361676619

A rigid-flex PCB is a circuit board made by combining a flexible PCB and a rigid PCB through lamination and other processes, according to relevant process requirements.

Advantages: Rigid-flex PCB combines the characteristics of both FPC and rigid PCB, making them suitable for products with specialized requirements. They offer both flexible and rigid areas, significantly helping to save internal space, reduce the volume of finished products, and improve product performance.

Disadvantages: Rigid-flex PCB requires numerous production steps, resulting in high production difficulty, low yield rates, and significant material and labor investment. Consequently, they are relatively expensive and have a long production cycle.

| material | FPC | Number of layers | 2 |

| copper thickness | 1oz | Plate thickness | 1.6mm |

| Minimum aperture | 0.15mm | Min. trace spacing | 0.065mm |

| Min. trace width | 0.065mm | Surface Treatment | Immersion Gold |