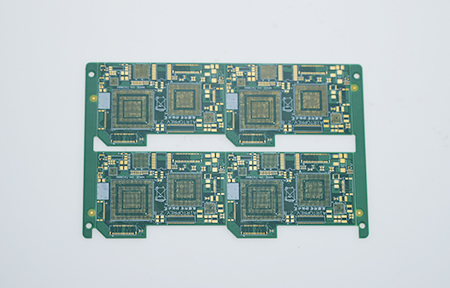

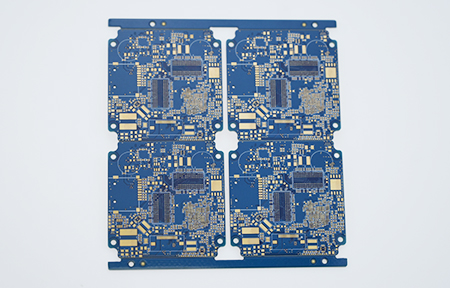

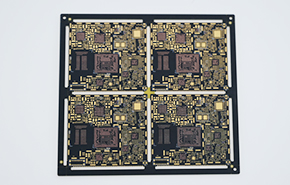

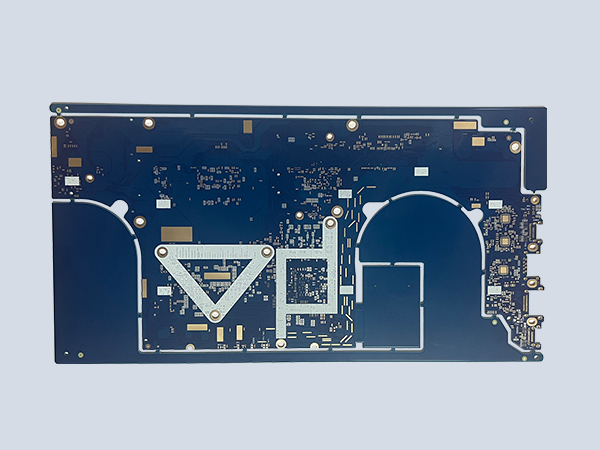

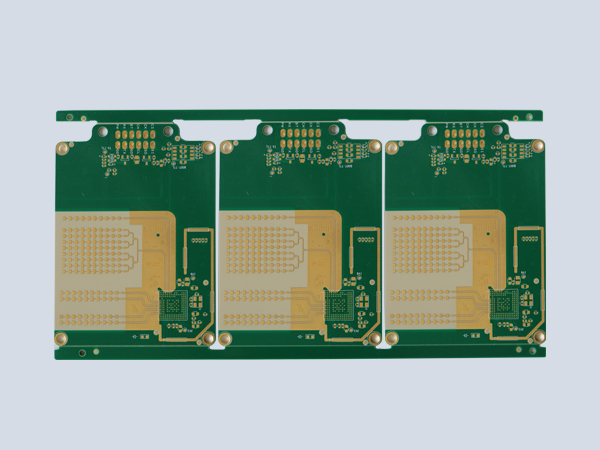

HDI blind & buried via PCB

HDI is an abbreviation for High Density Interconnector, which is a technology used in the production of printed circuit boards. It is a type of circuit board that uses micro blind buried hole technology to achieve a relatively high distribution density of circuits.

Phone:15361676619

HDI is an abbreviation for High Density Interconnect. It is a type of printed circuit board (PCB) technology that uses micro-blind buried vias to achieve a relatively high trace density. HDI is a compact product designed for low-volume users.

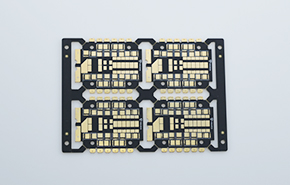

Blind vias: These are vias that connect traces on inner layers of a PCB to traces on the surface without penetrating the entire board. (Generally used on PCB with four or more layers.)

Buried vias: Buried vias connect traces only between inner layers and are invisible from the PCB surface. (Generally used on PCB with six or more layers.)

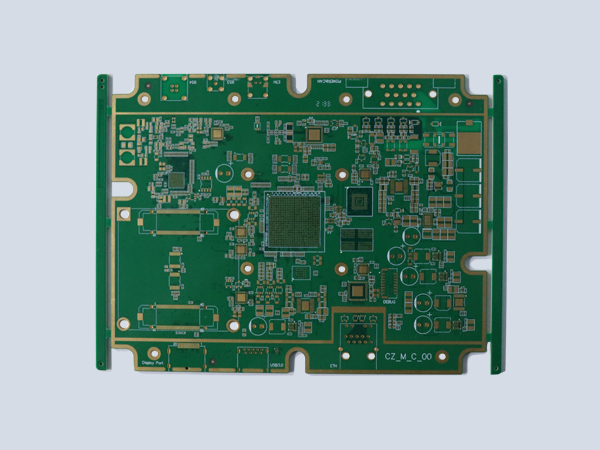

Advantages: They increase trace spacing.

Disadvantages: The process is costly and is not commonly used in electronic products, except for very high-end products.

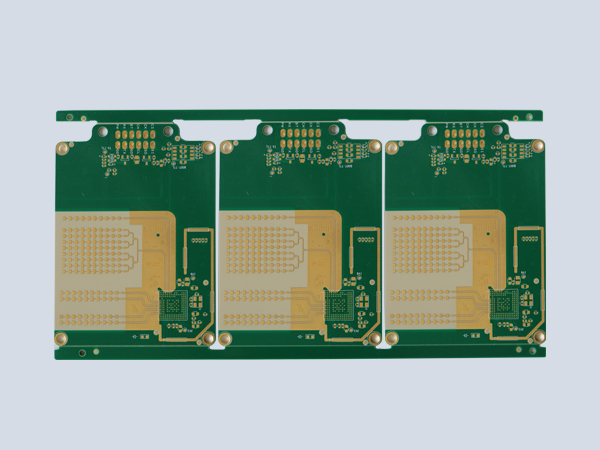

| material | Rogers+FR4 | Number of layers | 6 |

| copper thickness | 1oz | Plate thickness | 1.6mm |

| Minimum aperture | 0.1mm | Min. trace spacing | 0.075mm |

| Min. trace width | 0.075mm | Surface Treatment | Immersion Gold |